What Exactly Are Custom packaging Boxes Called?

Those days are long gone when shipping an item to a consumer required nothing more than finding the most inexpensive plain cardboard box available. Customers in today's market are drawn in by the outside of a box before they ever open it. In this instance, the manner in which you package it will reveal a great deal about your business. Why wouldn't you want to create a good first impression, particularly on those who are buying a house for the first time? Here's where specialized boxes come in handy!

In a word, custom packing boxes are constructed in a manner that is tailored specifically to the requirements of the organization. They create brand loyalty by impressing consumers with incredible visuals, ensuring the safety of products, complementing advertising methods, and ensuring product quality.

When the customer orders a bespoke box, they have the option of specifying the box's form, size, material, color, and stylistic preferences. The customisation requirements will, in most instances, be established by the product

Let's go even further into the topic of custom boxes and all they have to offer by learning more about them.

How are Individually Tailored Boxes Made?

The following two materials are the most common choices for this kind of packing, however custom products boxes may be manufactured from a variety of materials:

Whiteboard made of virgin fibres is referred to as paperboard SBS, which stands for solid bleached sulfate. You have the option of purchasing it coated or uncoated. It is also typically flat and light, making it an excellent material for printing. It is not difficult to cut, fold, emboss, or stamp with heated foil. This material is appropriate for use in the packaging of medicinal products, retail goods, and several other types of high-end packaging.If you need a white card product box, you can contact SIUMAI!

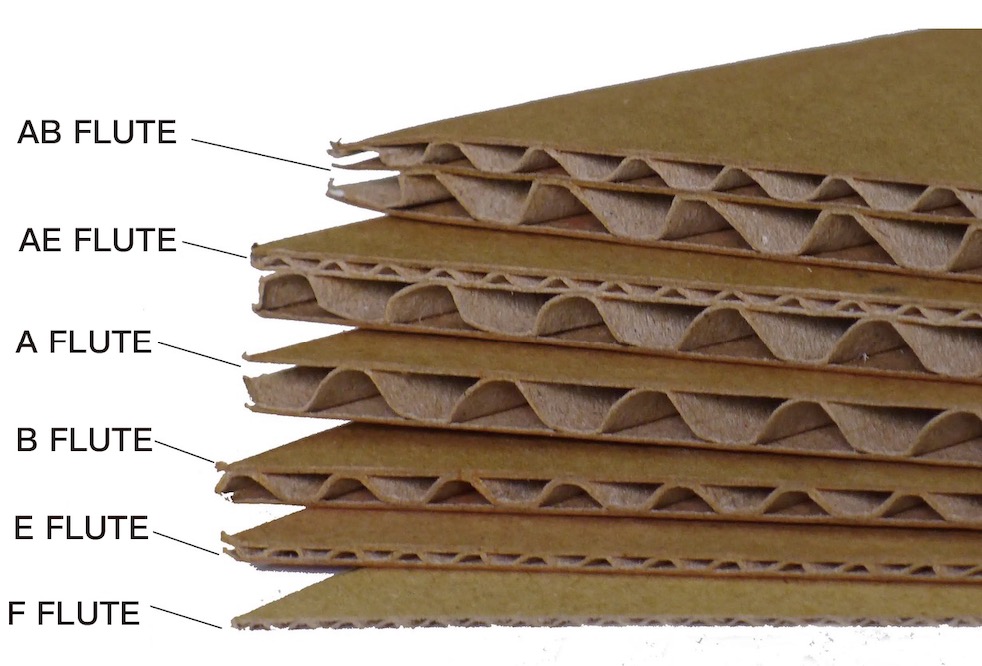

The construction of corrugated board consists of laminating paperboard with fluted paper in the centre. The fluted paper creates a cushioning effect inside the box, which helps to preserve the primary product. Depending on how delicate your item is, you have the option of selecting between a single-wall or double-wall structure for the packaging.This is a great choice for corrugated shipping boxes and custom mailer boxes

Now that you know what materials are used to make custom packaging boxes let’s dive into the making process.

Design and Graphics

Before we can begin the process of producing your custom printed boxes, we need that you first give the design for them. After all, you are aware of the information that you want to provide to your clients or of the aspects of your business that appeal to them.SIUMAI is able to assist clients in the creation of designs depending on the colors, sizes, and visual components that they require. Designers advocate using typefaces that are thicker or bolder for readable printing. During the printing process, this helps to guarantee that small elements such as serif typefaces, which have a fairly faint appearance, are not lost.We can offer our clients two options:

01Based on the premise that we are a factory, we are not particularly good at pattern design compared to structural design. Each company and each customer has his own corporate culture and core development pursuits.

We believe that the company's design department will better design works of art that fit the company's brand culture and develop ideas.

Likewise, each country's culture and popular patterns differ from each other.

We respect the culture of each country, if you are looking for an excellent graphic design studio in your own country to design, this may help you to have packaging that is more in line with local market trends.

As a factory, we can provide relevant process advice and production feasibility guidance for art works.

02 If you have not found a very suitable pattern art design expert for the time being. No relationship, we have established a deep ally with the design studio of Zhejiang Sci-Tech University.

It is a one of Chinese key university founded in 1897. There are super-class design students in it.

We hope to provide students with employment opportunities through their role in society and help them show the most wonderful and innovative artistic creations to the society.

You only need to pay a certain design fee to the designer, and communicate the style and ideas of good intentions, and the design plan will be given to you within two weeks.

Printing

Of course, no matter which option you choose, we will prepare your products packaging box for further prepress production. These include:

*Files must be printed four-color files in CMYK (can include Pantone spot colors)

*If the design is rich in color, it is recommended to reduce the Pantone color, which will help improve the accuracy of the printed color. If you don't use many colors and the monochromatic color block area is large, it is recommended to use Pantone colors.

*Black text, please use monochrome black when designing (C:0;M:0;Y:0;K:100)

*Check whether the bleed of the printed document is correct, usually 3mm out of the dieline.

* Whether all texts are turned to curves. The fonts downloaded in the software of each computer are different. We need to convert the text into curved outlines before sending the design files.

*Printing pattern, text must be 300DPI or above, the format is CDR, AI vector graphics. It is not recommended to make design files in PS, as there will be jaggedness and blurred edges after printing.

*Printing the same color on paper of different materials will show different color blocks, we need to carry out special file processing according to different printing paper.

*The more processing steps will increase the time cost of production, we need to make a reasonable printing plan.

and many more

The pre-printing work requires our experts to be attentive and professional at all times. We seek to help you turn your packaging wishes into reality and working hard until you are satisfied!

Customized box type

The following is a list of the several kinds of specialized boxes from which you may choose according to the nature of your enterprise:

Mailer Boxes

A mailer box is a piece of paperboard packaging that may be easily assembled. It has tabs that interlock with one another and dust flaps that keep it together without the need of tape or glue. Corrugated cardboard, often of the E flute (1/16") or B flute (1/8") kind, is used to construct mailer boxes. As a result of the box having multiple sides rather than just one, it is inherently more robust and resistant to harm than other forms of paperboard packaging.

Mailer boxes are the perfect choice for packing gifts and retail items. In addition to this, they are an outstanding choice for subscription boxes and several other types of promotional packages.

Custom Shipping Boxes (RSC or Regular Slotted Carton)

These are the most typical kinds of specialized boxes that may be ordered. A mailing box, much like a mailer box, is often made out of corrugated cardboard, namely either B flute or C flute.

Larger and heavier commodities, such as food items, electronics, and textiles, need the use of corrugated shipping boxes because of their size and weight.

Because they may be stacked, shipping boxes are an excellent choice for the storage in warehouses. However, in order to assemble them you will need to use tape and put in more work.

Custom products boxes (Folding Cartons)

Product boxes may be seen on store shelves, and they come in a wide variety of dimensions and configurations. Before being cut, folded, and glued together, they are often fabricated from paperboard and printed with various works of art and designs.

The final product is sent to the client in an unassembled state. They are required to first put together the boxes and then stock them with the items that will be sold. Products for the beauty industry, alcoholic beverages, and luxury goods are examples of commodities that are often packed in folding cartons.

Folding cartons are the most lightweight of all the several kinds of bespoke boxes. In addition to this, they are simple to pack, seal, and transport.

Custom rigid boxes

The two-piece rigid setup box is a special kind of product box that is not seen anywhere else. The product is held in place by one of the pieces, while the other serves as the cap. This folding rigid box is used frequently in the packaging of high-end products like smartphones, jewelry, and expensive watches. It is known for its exceptional strength. There is no limit to the number of ways in which a rigid box may be designed to be fully original to the tone and purpose of your brand.

Is It Worth It to Get Custom Packaging boxes?

It could be tempting to go with the choice of packing that costs the least. Nevertheless, it is not a good thing for the safety of your goods, particularly if the material is not created in the correct size or does not have the appropriate padding. Investing in tailor-made packaging solutions is a tried-and-true method that not only ensures the safety of your goods but also helps you save expenses in the long run. More significantly, a higher-quality and well-designed bespoke box will give your customer with a better purchasing experience. This will help you to remain in their thoughts and promote repeat purchases, which will result in more sales for your business. Therefore, it was worth it!

Post time: Sep-14-2022