The foil stamping process is a printing process commonly used in packaging design. It does not need to use ink in the production process. The hot-stamped metal graphics show a strong metallic luster, and the colors are bright and dazzling, which will never fade. The brightness of bronzing greatly exceeds the effect of gold and silver ink printing. Make the product more high-end and exquisite after it is produced. The foil stamping is widely used, and is often used in carton packaging, book covers, publicity advertisements, and daily necessities. After the product is foil stamped, it can be packaged and shipped immediately with high efficiency.

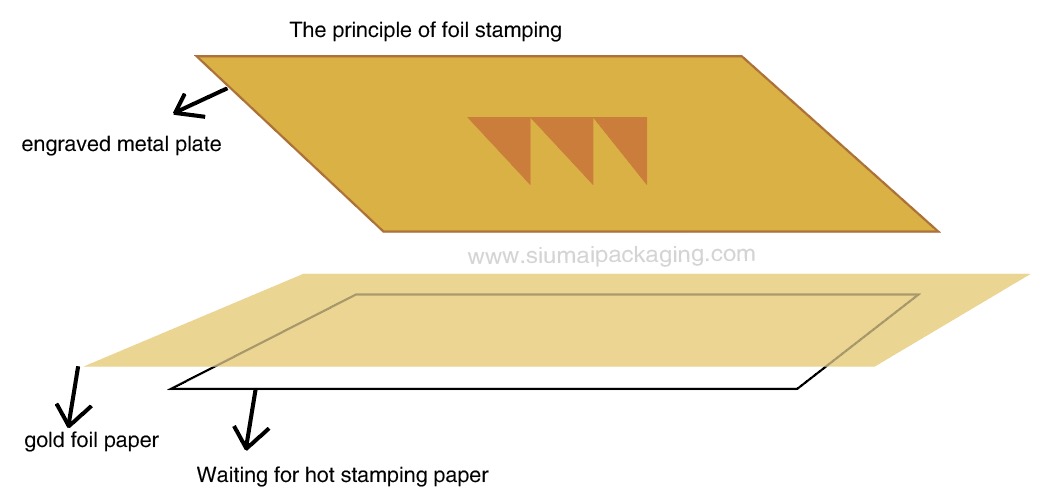

We will introduce the production principle and effect in detail through the process of foil stamping

The foil stamping process includes:

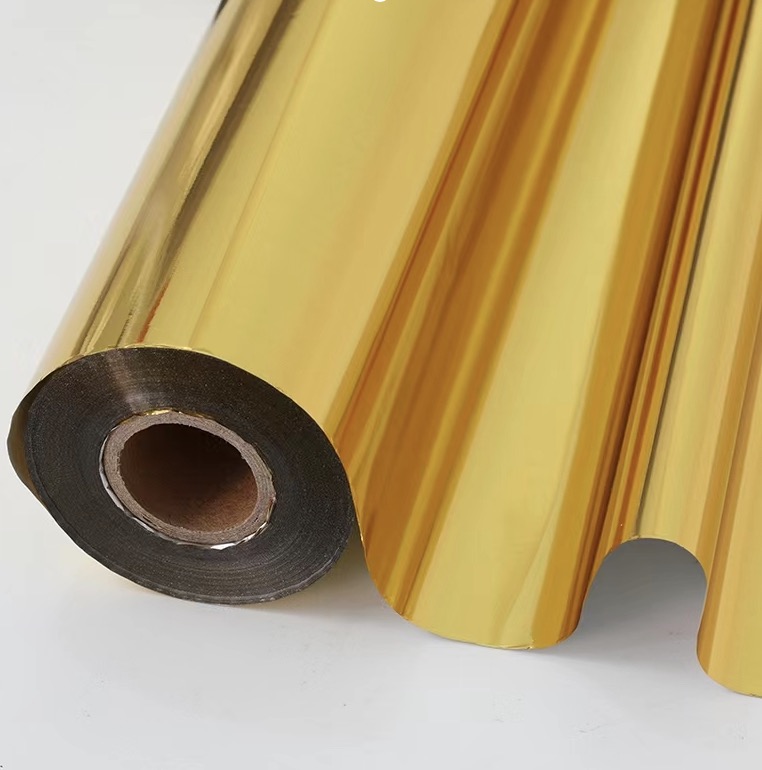

1.Making a patterned metal plate

2.Loading the plate

3.Prepare the anodized aluminum

4.Heat the metal plate to around 100 to 150 degrees Celsius

5.Transfer the anodized aluminum to the paper by pressure

6.See if the sample is success

7.Mass production

The main factors affecting the quality of foil stamping

*Temperature

Temperature has a very important influence on hot stamping, and the temperature must be controlled within the specification range to ensure that the dyeing resin layer and the adhesive are properly melted to achieve good transfer of the aluminum layer.

If the temperature is too high, the hot-stamped paper will lose its brightness and lose its metallic luster.

If the temperature is too low, the hot stamping will be weak, easy to fall off, and the printed pattern will be damaged.

*Pressure

The pressure is determined by the size of the hot stamping pattern, and the size of the hot stamping pressure also affects the adhesion of the anodized aluminum.

If the pressure is insufficient, the anodized aluminum cannot be transferred to the paper well. There will be problems such as imprinting and blurring.

Post time: Apr-15-2022